One of the most common problems facing kitchen sinks is the accumulation of grease or oil residues down the tube. Even if your plumber has probably warned you to avoid such materials from being poured into the pipe, over time it becomes habitual or just simply becomes unavoidable. Thus, the need to use grease traps.

Grease traps are also known as grease interceptors or grease converters. The Uniform Plumbing Code (UPC) differentiates grease traps from grease interceptors based on the waste water flow rate that can be dealt with by the device. Grease traps can handle less than 50 gallons per minute while grease interceptors can handle more than 50 gallons, thus they are more common in commercial or industrial establishments.

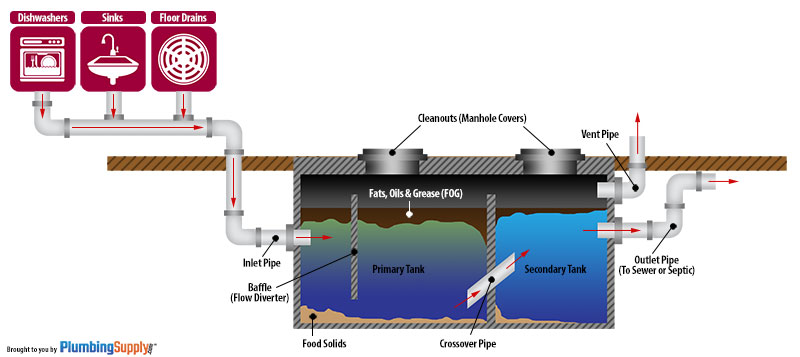

Grease traps can reduce the amount of fats, oils and greases (FOGs) and other solid waste materials by restricting their flow before they enter the waste water disposal system. Thus, the risks of drain and sink blockages are reduced. Solids that will be accumulated or remain deposited on the bottom of grease traps are then removed during grease trap cleaning and maintenance. Grease traps can be emptied when the sludge fills a quarter of the tank. Regular cleaning should always be observed to avoid rotting of FOGs, which could result in odor or gas build-up.

The grease trap installation process usually involves identifying the size of the grease trap that you require, determining where to install it, and connecting the parts, which may vary from one manufacturer to another. Unlike their commercial counterparts, residential grease traps are much easier to install and clean, but getting an expert to do these tasks will ease your worries on whether you are doing it the right way or missing out on something important. Still have questions? Ask a plumber now and get that needed protection for your waste water disposal system.